How to make valves? How much do you know about it?

The Manufacturing Technology Features of Valves

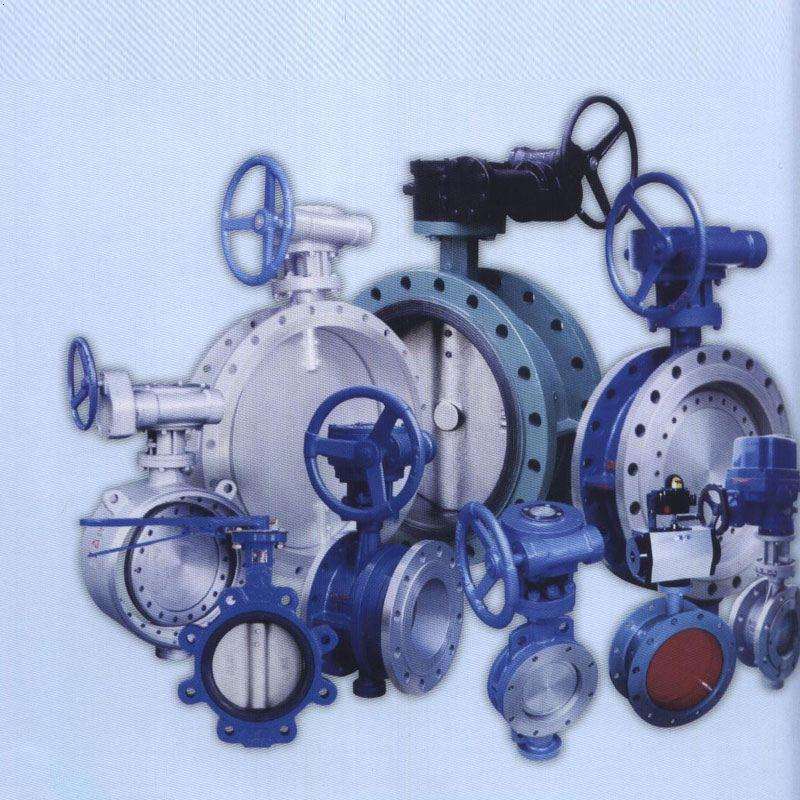

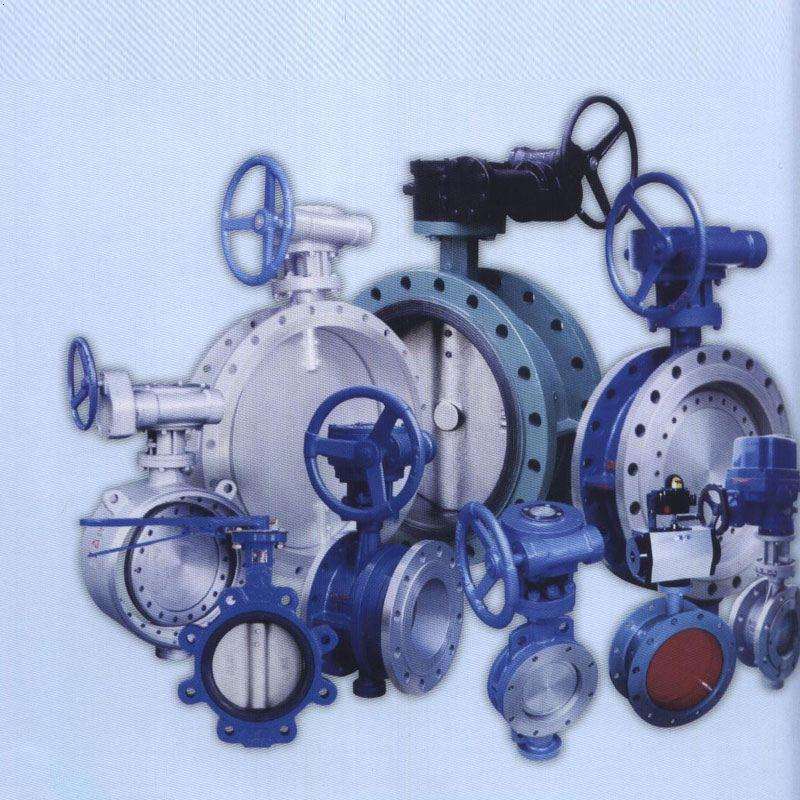

When first seeing

valves, you will find that

valves have a few components, simple structures and general precision.

Valves belong to simple parts in the mechanical industry, however, the central seal parts of valves have extremely high requirements. The manufacturing technology of valves is complex and difficult, and what kinds of technology features should we pay attention to?

1.

Manufacturing Materials

Widely used in many fields of national economy,

valves in different varieties have diverse specifications, and they are applied to various working conditions such as high temperature and high pressure working conditions, low temperature and deep cooling working conditions, flammable, explosive, toxic, and corrosive medium conditions, etc., which put extremely strict requirements on the materials of valves.

Valves are not only made of cast Iron, carbon steel, and structural alloy steel, but also made of plenty of CrNi stainless steel, CrMoAI nitride steel, CrMoV heat resistant steel, CrMnN acid-resistant steel, precipitation hardening steel, two phase stainless steel, low temperature steel, titanium alloy, monel alloy, hastelloy alloy and G0CrW hard alloy, etc. These high alloy materials have poor performance in the casting and welding processes, which brings much inconvenience to the manufacturing process. In addition, most of these precious materials are with high alloy, high strength and high hardness, and there are many difficulties in choosing, preparing and purchasing these materials. Some materials are hard to be purchased because there is only small consumption of them.

2.

The Structures of Cast Blanks

Most of valve blanks adopt the thin-shell castings with complicated structures, which requires not only good quality of appearance, but also the compact inherent quality and superior metallographic structures. There should not exist such defects as blowholes, shrinkage cavities, sand inclusions and cracks. Therefore, the casting technologies are complex and the heat treatment technologies are difficult. In the mechanical industry, it is more difficult to cast the valves' pressure-bearing thin-shell casting blanks than to cast other mechanical components' foundry goods.

3.

The Machining Process

Due to the poor cutting performance of most materials with high strength, high hardness and high corrosion resistance. Both high alloy stainless steel and acid-resistant steel have such disadvantages as high toughness, high strength, poor heat dissipation and severe working hardening tendency, etc. Therefore it is hard for these materials to meet the required dimensional accuracy and smooth finish, which brings difficulties to the tool, technology and equipment of machining. Besides, the valve sealing surface's requirements for machining accuracy, cooperation angle, smooth finish and matched sealed auxiliaries are high, which also brings great difficulties to the machining.